페이지 정보

본문

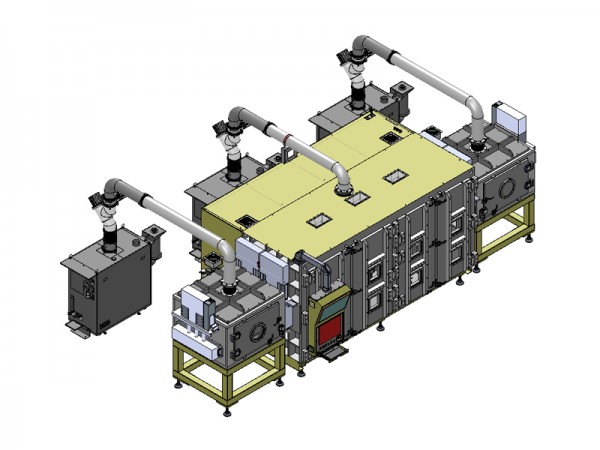

Vaccum type system

Roll to Roll Vacuum Laminator

| Description | General Specifications | ||

|---|---|---|---|

| Use | This device is a system that uses a hot laminator roll in a vacuum chamber to attach DFSR (ABF) film at uniform pressure without generating voids. | ||

| Model name | DIL-DFSR-510-V | ||

| Process | DFSR tack welding ->Hot roll (rubber) Laminator->Hot roll (Steel) Laminator ->Hot roll (Steel) Laminator ->Cooling | ||

| Load lock chamber | By installing separate chambers in front and behind the main chamber |

Product Description

Characteristic

1. Productivity: At least 10-20% improvement compared to existing equipment

2. Stability: Possible to work with relatively low pressure as the process is performed through line contact rather than surface contact.

3. Quality: Free from air bubble issues as the laminating and hot pressing process is performed in a vacuum condition.

4. Convenience: Pre-processing is easy as the front door of the vacuum chamber is opened and closed, and since it is a fully automatic equipment, it is easy to operate and manage.

5. Maintenance: The rear driving part of the vacuum chamber is designed for easy maintenance.

- Prev.3SP Fully Automatic Printer + CCD:DIP-3SP series 24.11.21

- NextOne table type Automatic Printing system 24.11.21